GURSAN has been working on mineral processing technology

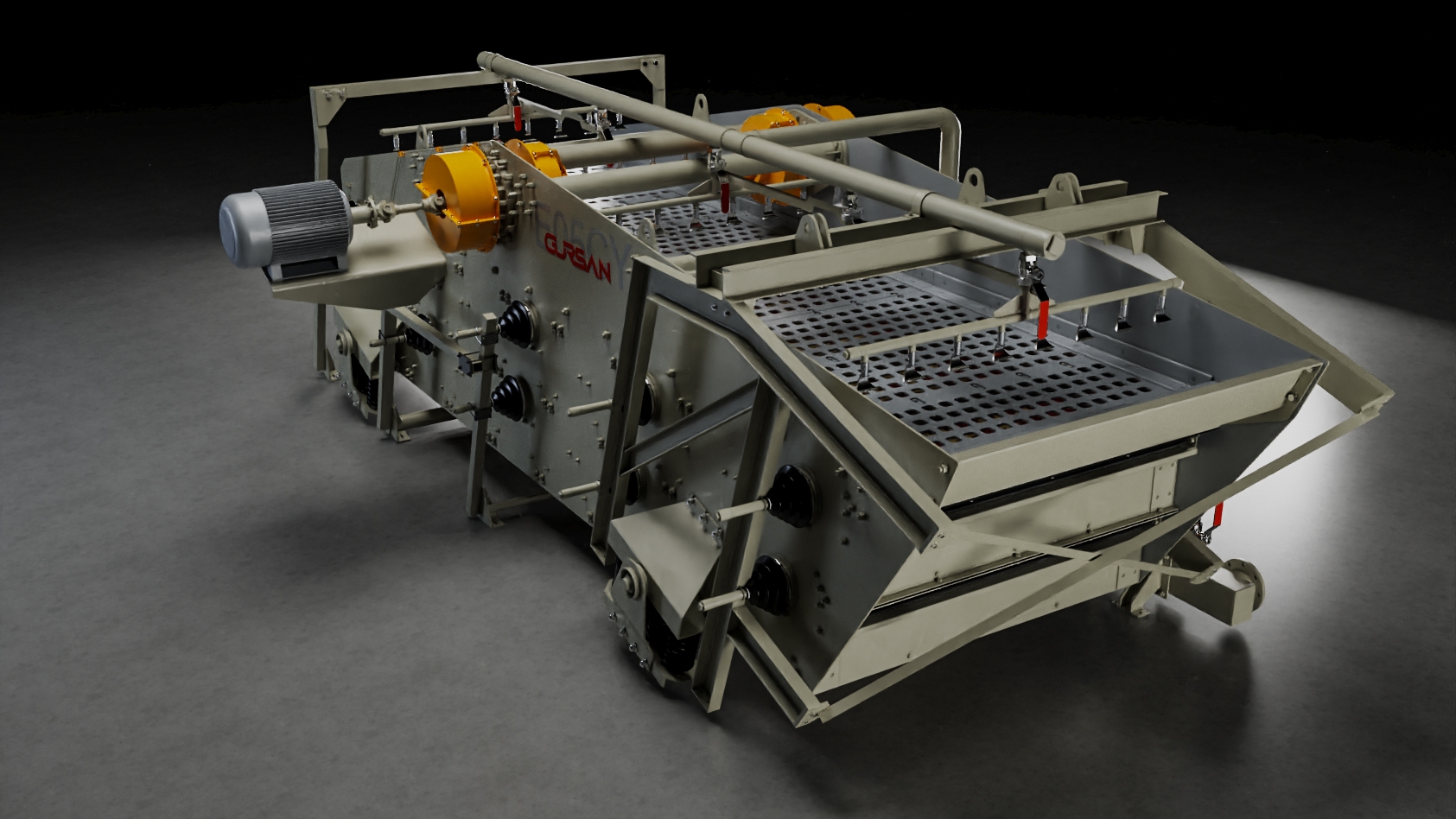

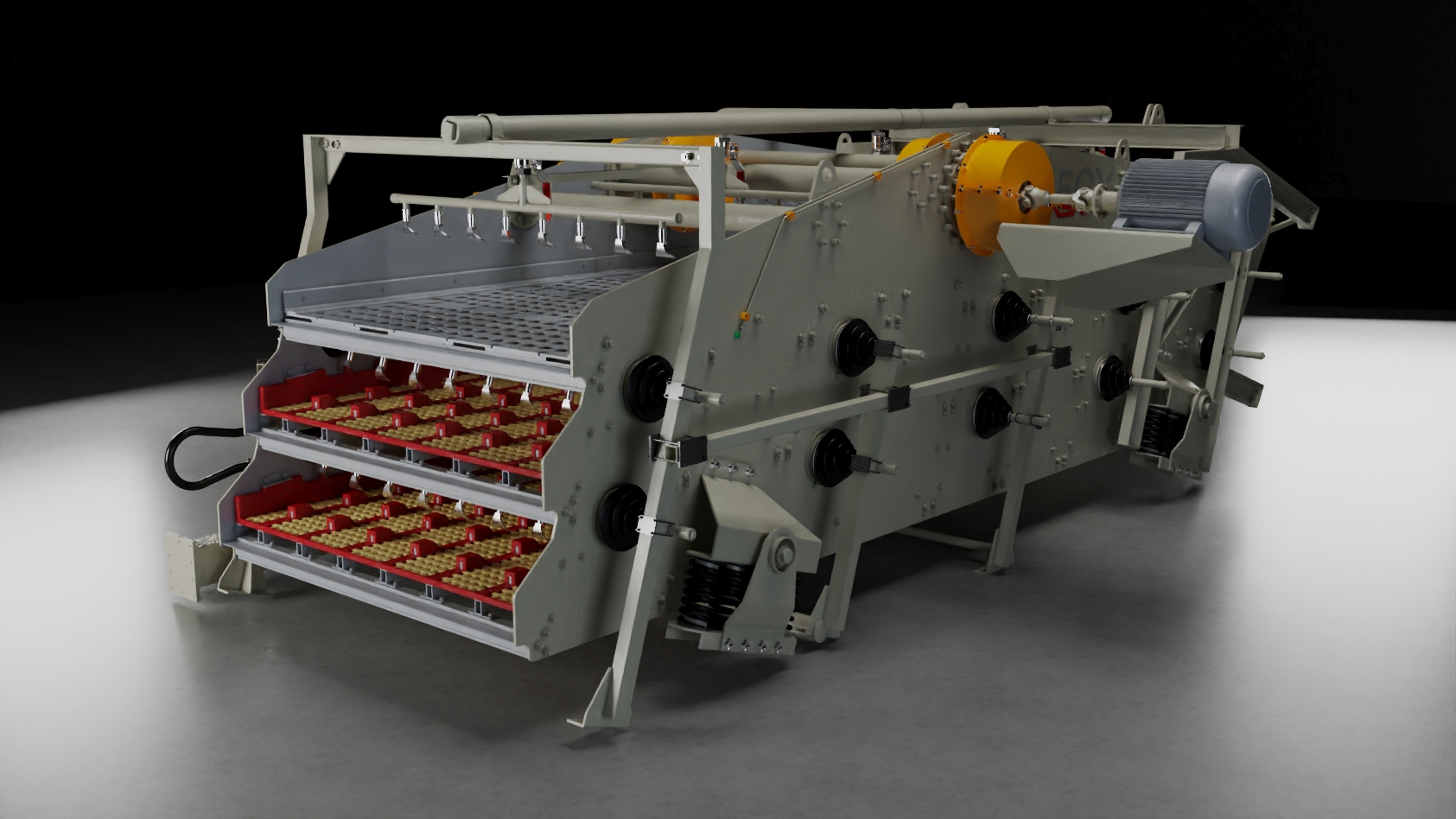

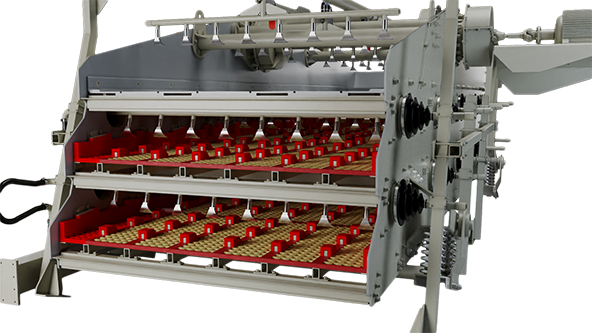

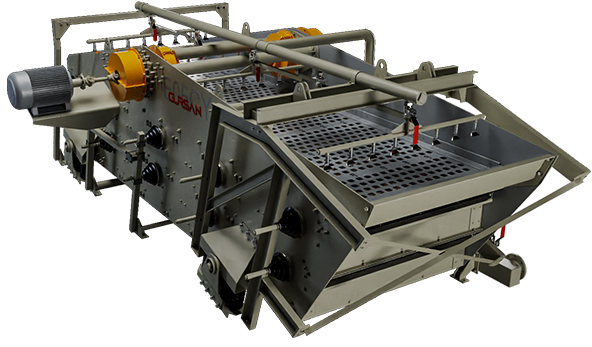

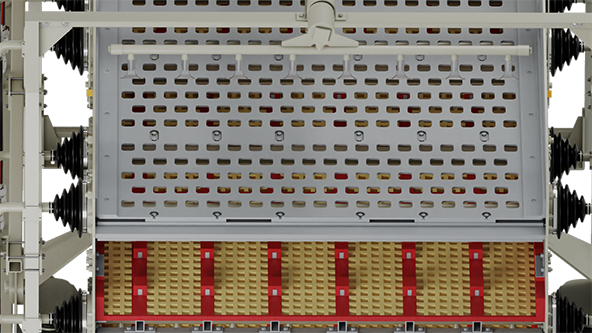

VIBRATING SCREENS

The fed material is accelerated towards the front side just at the instant of contact with the rear side of the screen. Thus the pitch of the material at the screen surface decreases rapidly and disperses at the surface of the screen homogeneously. Meanwhile, it leads a bulk amount of fine material to the lower section rapidly within the first meter, and therefore the load of the most loaded part of the screen is distributed and balanced fast. Then the remaining near the size and undersized material distributed on the screen surface is decelerated and effectively screened.

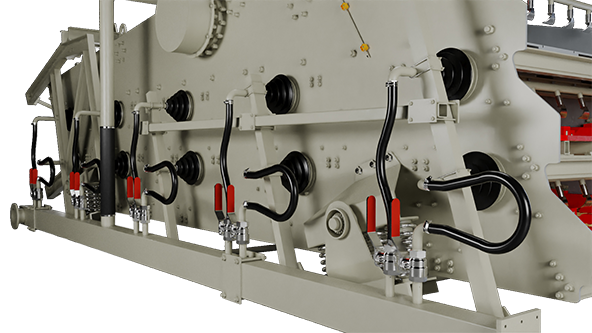

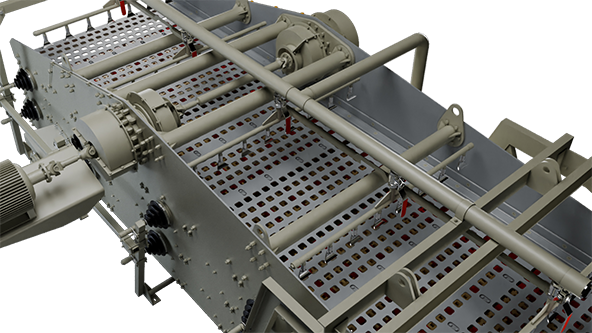

The vibration system is designed to reach high RPMs that are required for efficient screening, to offer practical setup according to changing situations, and to provide a fast and easy spare part replacement. This practical system that provides efficient oscillation consists of two identical vibration units (right and left) and an intermediate Cardan shaft that transmits the power that is generated by the motor to the other and synchronizes these two vibrators. This system eliminates the imbalance problem that occurred due to belt lighteners in v-belt systems. It does not transmit the vibration of the screen to the motor and no extra load is imposed on the motor shaft during stop and start.

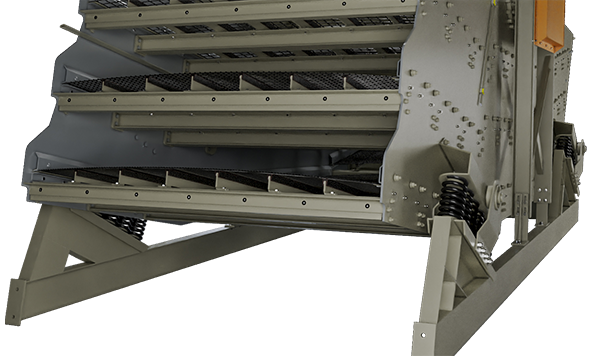

All screens are equipped with vibration dampers to absorb extensive vibrations due to starts and stops.

Deck clearance is kept larger to provide easy replacement of screen meshes.

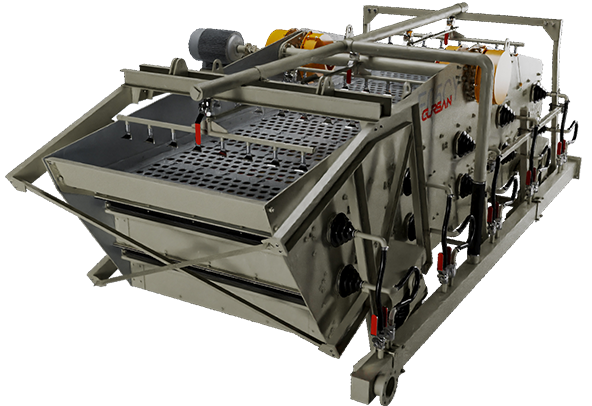

Screens are integrated into the active washing system. An active washing system is available for all models in order.

GURSAN Vibrating screens deck angle is 18 degrees. It is possible to reach a more efficient screening capacity by changing the deck degrees to 15, 25, and 35 degrees using them as a banana screen.

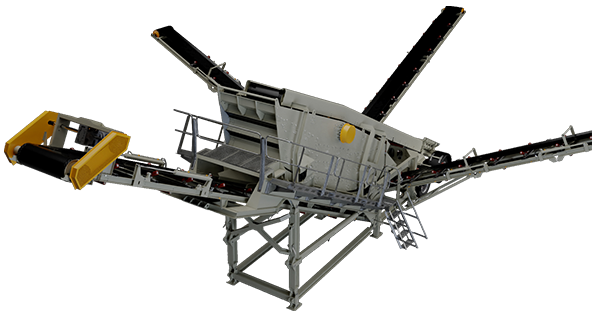

GURSAN Vibrating Screens can be produced on stationary or mobile types according to customer demand.

The body structure of the screen is designed as modular. All of the components that form the body are manufactured at CNC counters so as to facilitate the replacement of components that will be delivered from our factory in case of a renewal necessity in the future or whenever it is required.

If coarse screening is done, screen upper levels can be produced from perforated sheets or modular sheets cut in grille type. Therefore both screening is performed without any problem and measures are taken against abrasion due to coarse feeding.

On the other hand, our screens can be delivered totally enclosed as a measure against dusting.

PRODUCT VIDEO

OTHER PRODUCTS

PRODUCTS

- Crushers

- Vibrating Screens

- Belt Conveyors

- Primary Plants

- Feeders

- Classifiers